News

Safety First: Proper Handling and Operation of High-Pressure Jetting Equipment

Working with high-pressure jetting equipment demands not only technical knowledge but also a commitment to safety. Whether you are clearing a blocked drain or carrying out surface preparation, understanding how to handle this powerful equipment correctly is crucial to avoid accidents, reduce downtime, and maintain optimal performance. At Flowplant, we are passionate about promoting safe practices in every aspect of high-pressure jetting operations. Here’s a comprehensive guide on proper handling and operational safety for high-pressure jetting equipment.

Why Safety Matters in High-Pressure Jetting

High-pressure water jetting systems can operate at pressures exceeding 3,000 bar. Such extreme pressures make jetting tools highly effective but also introduce a significant safety risk if used incorrectly. Proper training and awareness are key to minimising these risks. Improper handling can lead to serious injuries, environmental damage, and even fatalities, making safety a non-negotiable priority.

Key Safety Guidelines for Handling High-Pressure Jetting Equipment

- Wear the Right Personal Protective Equipment (PPE)

Operators and those working in proximity to high-pressure jetting should always wear appropriate PPE. This typically includes:

– PPE such as gloves, face shields, waterproof protective suits, and boots designed to withstand high water pressure.

– Hearing protection to mitigate noise exposure from pump systems.

– Helmets and goggles to protect against flying debris.

- Proper Training and Certification

It’s essential for operators to be certified and trained according to the Water Jetting Association (WJA) standards. Training ensures that individuals are fully aware of the risks, equipment functionality, and emergency protocols. Flowplant offers WJA-accredited training, including Safety Awareness and Drain, Sewer & Surface Preparation (DSP) courses, to equip users with the knowledge they need.

- Inspect Your Equipment Before Every Use

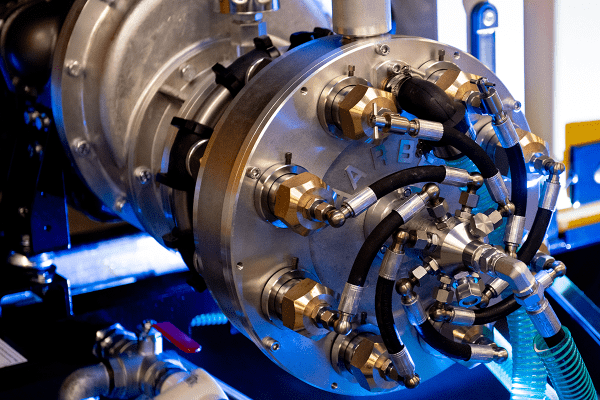

High-pressure jetting systems include pumps, hoses, and nozzles, all of which should be thoroughly inspected before each use. Look for signs of wear, such as leaks, cracks, or kinks in hoses, and ensure all seals are intact. Regular inspection reduces the risk of unexpected failures during operation, which could lead to accidents.

- Follow Proper Start-Up and Shutdown Procedures

When operating high-pressure jetting equipment:

– Ensure the equipment is securely anchored and stable.

– Never leave equipment running unattended, especially in hazardous environments.

– Always depressurise the system before performing any maintenance.

At Flowplant, our complete range of high-pressure jetting units, including models such as the Eco Pro 3000 and Jet Buggy, are always equipped with safety features, but operator vigilance remains critical.

- Maintain a Safe Distance

Where possible, operators should always maintain a safe distance from the jetting nozzle to avoid accidental injury. High-pressure jets can easily puncture the skin or cause more severe injuries if mishandled. Establish a controlled area around the worksite to prevent unauthorised personnel from entering the danger zone.

- Understand Pressure and Flow

It’s crucial to match the correct pressure and nozzle for the task at hand. Using the incorrect setup can lead to inefficient cleaning and may pose a safety risk. Flowplant’s Harben Pumps are designed for versatility and safety, with a range of pressures to handle different applications, from 2,000 PSI to 10,000 PSI.

Handling High-Pressure Hoses

The hose is often the most vulnerable part of a jetting system. Here are some critical points to remember:

– Daily Inspections: Check hoses for abrasions, cuts, and wear. Any damage can escalate quickly under pressure.

– Avoid Bending or Twisting: Ensure the hose is laid out flat without sharp bends, as kinks can weaken the hose and lead to bursts.

– Correct Hose Storage: When not in use, hoses should be properly coiled and stored in a dry environment to prevent degradation.

We’ve created a High-Pressure Hose Inspection Checklist to assist in daily maintenance routines, ensuring that safety remains the top priority. DOWNLOAD HERE >>

Stay Compliant with Industry Standards

Adhering to industry standards and legislation is not just good practice; it’s a legal obligation. Regular equipment inspections, proper certification, and up-to-date training help ensure compliance with health and safety regulations in industries such as construction, oil & gas, and drain & sewer cleaning.

Conclusion

In the world of high-pressure jetting, safety isn’t just an add-on – it’s a core element of every operation. Regular training, the use of appropriate PPE, and rigorous equipment inspections are essential to keeping operators safe and ensuring peak performance. At Flowplant, we are committed to providing not only the best high-pressure systems on the market but also the resources and training needed to use them safely.

Ready to enhance your safety practices? Download our High-Pressure Hose Inspection Checklist and explore our WJA-accredited training programmes to stay compliant and confident in your operations.

For more information on our high-pressure jetting solutions or to book training, contact us today at sales@flowplant.com or call 01722 325424, or complete the training enquiry form below.