News

The Power of Neolith Cleaning Chemicals: Enhancing Performance with Flowplant Jetting Machines

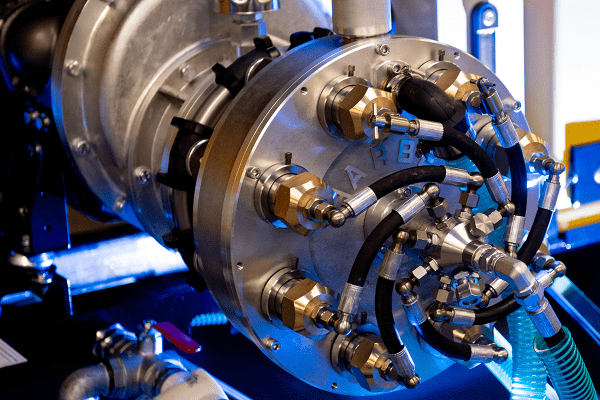

In high-pressure jetting, the effectiveness of cleaning can be influenced by two things: the power of the jetting machine and the quality of the cleaning chemicals used. At Flowplant, we’re dedicated to providing industry-leading jetting machines that deliver powerful results. But in some circumstances to truly maximise their performance, we recommend pairing Flowplant equipment with Neolith cleaning chemicals, specifically formulated to tackle a wide range of cleaning tasks with precision and efficiency.

Why Neolith Cleaning Chemicals?

Neolith is a trusted name in building cleaning chemicals, with a reputation for effective and environmentally conscious solutions. Their products are specially designed to target tough stains and deposits that accumulate on buildings, pavements, industrial equipment, and more. Combining Neolith’s powerful chemicals with our Flowplant machines allows for a seamless cleaning process that removes grime and tough deposits quickly, minimising time and resources spent on cleaning.

Key Benefits when combined with Flowplant Machines

- Enhanced Cleaning Power

Neolith cleaning chemicals are formulated to break down and dissolve stubborn dirt, algae, limescale, and other deposits that regular cleaning agents struggle to remove. When used with a Flowplant machine, the jetting action, combined with Neolith’s advanced formula, provides outstanding results in less time, reducing the need for multiple passes.

- Eco-Friendly Formulas

In today’s environmentally conscious world, using safe, eco-friendly products is more important than ever. Neolith cleaning chemicals are designed to be gentle on the environment while remaining tough on grime. This commitment aligns perfectly with Flowplant’s values, allowing us to offer cleaning solutions that perform effectively without harming the environment.

- Improved Safety

Neolith’s cleaning solutions are also designed with user safety in mind. Their chemicals are less toxic, with lower fumes and safer handling properties, making them ideal for both indoor and outdoor applications. Pairing our machines with Neolith products ensures a safer environment for operators, which is crucial when working with high-pressure equipment.

- Versatile Applications

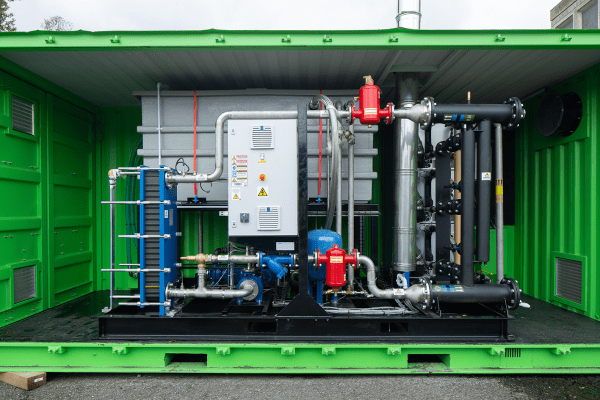

From building facades and pavements to industrial equipment and commercial spaces, Neolith’s range of products can tackle diverse cleaning applications. When used with Flowplant’s versatile jetting units, this combination offers adaptable solutions that can meet the demands of various industries, including construction, industrial cleaning, and facility management.

Popular Neolith Products for Use with Flowplant Machines

- Neolith 800 – This heavy-duty cleaner is ideal for removing stubborn algae, moss, and limescale deposits, making it perfect for use on building exteriors and pavements.

- Neolith Graffiti Remover – Designed to break down graffiti paint and ink, this chemical works exceptionally well with Flowplant jetting machines to remove graffiti without damaging the underlying surface.

- Neolith Degreaser – For industrial applications where grease and oil are common, Neolith’s degreaser works efficiently with our machines to cut through greasy build-ups on machinery and equipment.

A Complete Solution for Efficient Cleaning

Combining Flowplant’s high-performance jetting machines with Neolith’s powerful, eco-friendly cleaning chemicals creates a superior cleaning solution. This partnership enhances cleaning power, ensures equipment protection, and delivers safe, environmentally responsible results. Whether you’re tackling a building facade, industrial machinery, or graffiti removal, the Flowplant and Neolith combination provides an efficient and effective solution that professionals can trust.

For more information about Neolith cleaning chemicals and how they can enhance your Flowplant equipment, get in touch with our team. Let us help you find the right combination of power and performance for your specific cleaning needs.

Useful links: