News

Using a Jetter for Root & Scale Removal From Drainage Systems

High pressure water provides a safe, clean and efficient method for removing scale, grease and roots from drainage systems and at Flowplant we offer a wide selection of accessories to complement our jetters. For root and scale removal these fall into two different categories – mechanical jets and non-mechanical jets.

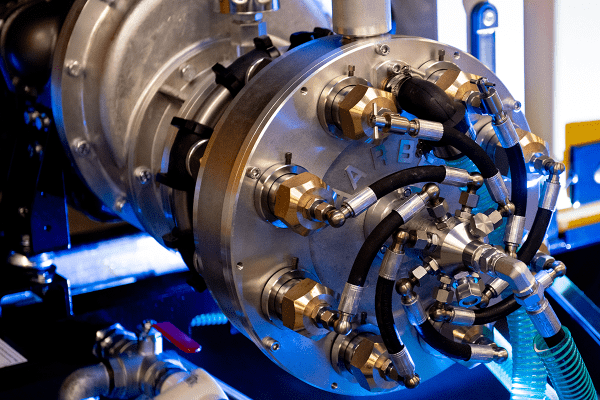

Mechanical jets use the high pressure water to provide propulsion up the pipe and also drive a spinning rotor. The rotor can be slow or fast spinning and it normally has either saw blades or chain flails attached to it. With these mechanical jets it is the blade or flail that comes into contact with the obstruction and cuts or abrades it until the pipe is clear. With careful operation, and it is often helpful to use them in conjunction with a camera inspection system, they can be very effective in removing larger tap roots or harder scale deposits. They can be ideal if you have a less powerful jetter because they rely more on jetter flow than jetter pressure to spin the rotor. It is quite possible with our Root Cutter Saw to achieve good results, even on thicker tap roots in a 225mm drain, if your jetter can give 45 l/min (10 gpm) at 140 bar (2,000 psi).

Mechanical jets use the high pressure water to provide propulsion up the pipe and also drive a spinning rotor. The rotor can be slow or fast spinning and it normally has either saw blades or chain flails attached to it. With these mechanical jets it is the blade or flail that comes into contact with the obstruction and cuts or abrades it until the pipe is clear. With careful operation, and it is often helpful to use them in conjunction with a camera inspection system, they can be very effective in removing larger tap roots or harder scale deposits. They can be ideal if you have a less powerful jetter because they rely more on jetter flow than jetter pressure to spin the rotor. It is quite possible with our Root Cutter Saw to achieve good results, even on thicker tap roots in a 225mm drain, if your jetter can give 45 l/min (10 gpm) at 140 bar (2,000 psi).

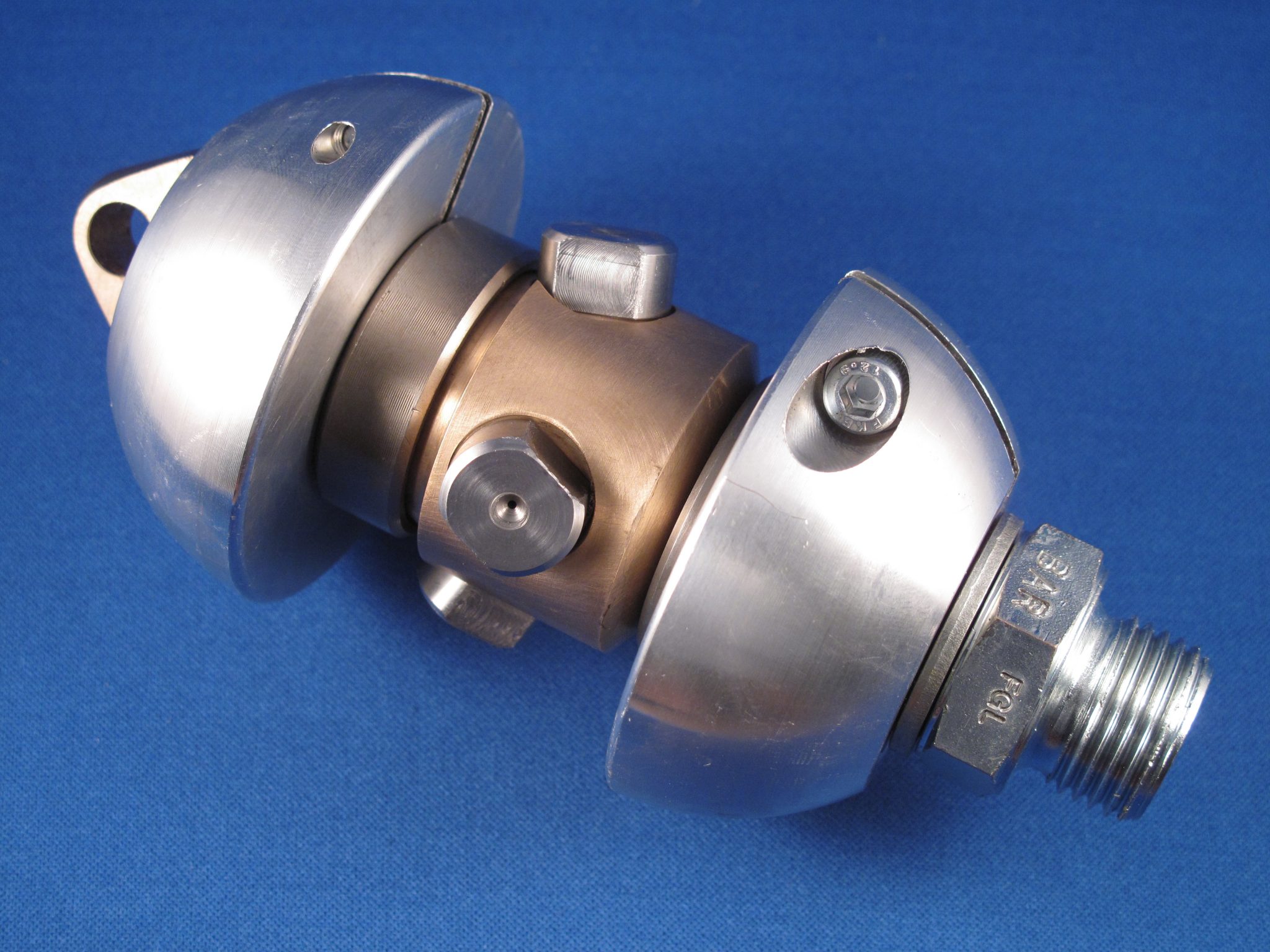

But it is the second category, non-mechanical jets, which dominate the accessory market for root and scale cutters on high pressure jetters. With non mechanical jets it is just the high pressure jet stream that cuts away the obstruction rather than any type of blade. They tend to have the advantage of causing less unintended structural damage to the drain surface, as long as they are not left to dwell in one position for too long, and they are very easy to set up, not requiring any form of centraliser unless they are being used in a larger diameter pipe.

At Flowplant, we have several different models of non-mechanical jets right up to our Aquaspin and Turbojet range with operating pressures of 1,000 bar (15,000 psi) suitable for removing failed liners and the hardest scale, down to our new Primus speed controlled nozzle. The Primus has a slow spinning jet head with 4 rear facing ceramic cutting nozzles and 3 fixed drive nozzles. The slow rotation speed, controlled by a special ceramic disc, allows the cutting nozzles plenty of time to chop through fibrous roots or scale as they pass by. At Flowplant we have found that pipes up to 225mm in diameter can be efficiently cleaned using a Primus driven by just 200 bar at 54 L/min (3,000 psi @ 12 gpm).

At Flowplant, we have several different models of non-mechanical jets right up to our Aquaspin and Turbojet range with operating pressures of 1,000 bar (15,000 psi) suitable for removing failed liners and the hardest scale, down to our new Primus speed controlled nozzle. The Primus has a slow spinning jet head with 4 rear facing ceramic cutting nozzles and 3 fixed drive nozzles. The slow rotation speed, controlled by a special ceramic disc, allows the cutting nozzles plenty of time to chop through fibrous roots or scale as they pass by. At Flowplant we have found that pipes up to 225mm in diameter can be efficiently cleaned using a Primus driven by just 200 bar at 54 L/min (3,000 psi @ 12 gpm).

Of course in common with all drain cleaning activities if you have more power available you can often get the job done much quicker which is why the Harben® 700 bar Century truck units paired with a simple but effective Turbojet is the descaling set up of choice for many contractors.