News

The Harben Pump: Revolutionising Drain and Sewer Jetting Since 1971

When it comes to drain and sewer jetting, efficiency and reliability are non-negotiable. Enter the Harben Pump, a game-changer that has been at the forefront of high-pressure jetting technology since its inception. Manufactured in the UK by Flowplant Group Ltd, the Harben Pump boasts a wealth of history, innovation, and unmatched capabilities that make it the preferred choice for professionals in the drain and sewer industry. It’s important to note that while Harben Inc., part of the Flowplant group, sells units into the US market, the Harben Pump is solely manufactured by Flowplant in the UK. This distinction ensures the highest quality and precision engineering synonymous with British manufacturing. Read on to find out how the Harben Pump is revolutionising the Drain and Sewer Industry.

A Brief History: From Trucks to Trailers

Before the arrival of trailer-mounted jetters, high-pressure jetting was a cumbersome affair. Heavy pumps mounted on large trucks used significant amounts of water at high pressure. The game changed in 1971 with the launch of the first Harben® trailer jetter. This compact powerhouse produced 2000 psi at 6 gpm, enough to clean a 100mm pipe and extend 40 meters up the line.

As high-pressure jetting gained popularity, the demand for greater reach grew. Bernard Hart, who founded Harben® alongside Allan Bennie in 1971, tackled this challenge head-on. He discovered that starving the pump of water created a pulse, causing the hose to “jump” farther up the pipe, revolutionising the efficiency of drain cleaning.

Unmatched Capabilities: What Sets the Harben Pump Apart

Ability to Run Dry

Harben pumps exhibit the remarkable ability to operate indefinitely without water. Even when pushed to maximum power for extended periods, these pumps remain undamaged, ensuring reliability in the toughest conditions.

Versatile Fluid Compatibility

Whether it’s fresh water, sea water, or various other fluids, the Harben Pump handles them all with ease, making it an ideal choice for diverse applications.

Solids Handling

With an impressive 150-micron tolerance, the Harben Pump is engineered to handle fluids with solids and debris, perfect for challenging environments.

Robust Reliability

The durability of the Harben Pump stems from its extraordinary dry-running capability, versatile fluid handling, and impeccable engineering. It’s built to last, providing reliable performance year after year.

UK Manufacture

Choosing the Harben Pump means investing in British excellence. Precision-engineered by Flowplant Group Ltd, these pumps represent the pinnacle of UK manufacturing quality.

The Engineering Marvel: How the Harben Pumps is revolutionising the Drain & Sewer Industry

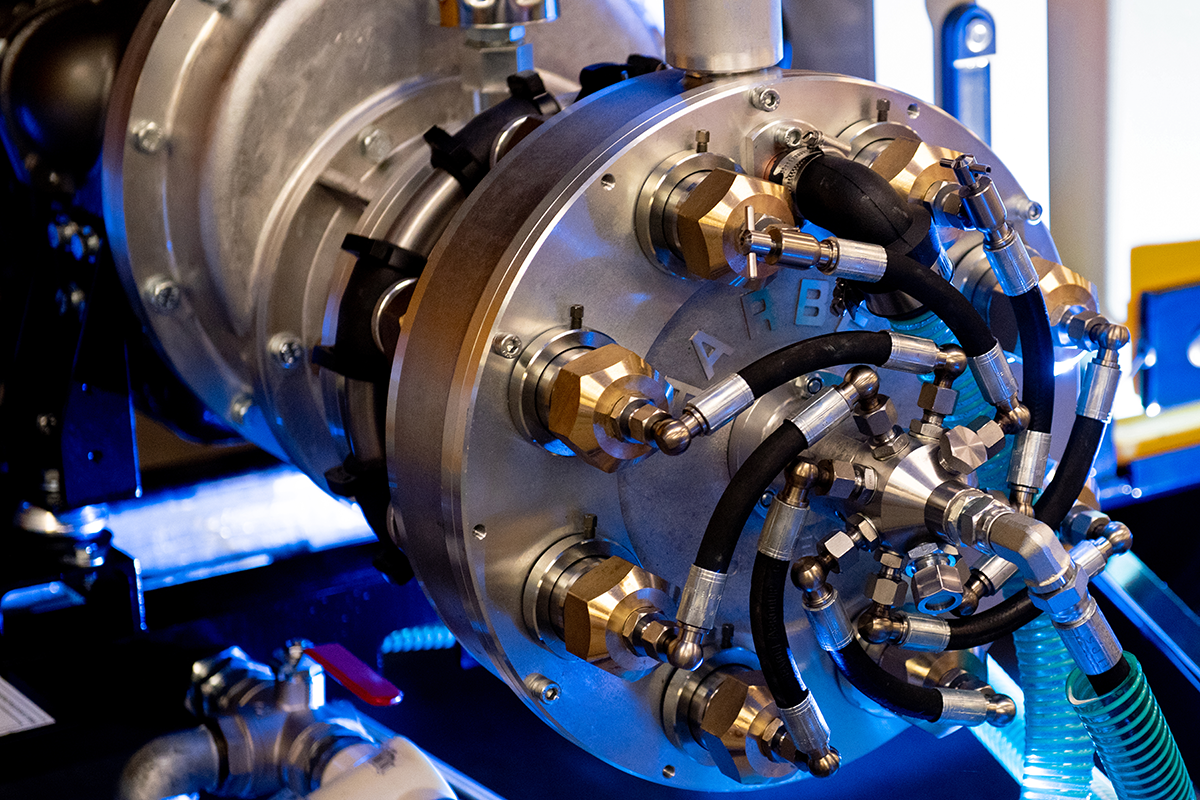

The Harben Pump operates on the radial piston design principle, utilising one-way valves in conjunction with tubular diaphragms fitted with internal supports. Here’s a closer look at its innovative mechanism:

Piston and Diaphragm System – As the piston advances, it compresses the diaphragm around the mandrel, expelling water through the delivery valve. The retreat of the piston draws water through the inlet valve, ensuring a continuous flow.

Oil-Flooded Crankcase – All mechanical parts, except the inlet and delivery valves, operate in an oil-flooded crankcase, unaffected by contamination or dry running. The HLP oil lubricates the moving parts and compresses the diaphragm.

Smooth Flow with Multiple Barrels – Standard diaphragm/barrel assemblies offer a choice of flows, depending on the number of barrels. Multiple barrels ensure a smooth flow with limited pulsations, enhancing performance.

Versatility and Power: The Harben Pump Range

The Harben Pump range caters to various needs with models like the Hi-Q, ‘P’ type, and Century Series pumps. These pumps offer pressures up to 700 bar (10,000 PSI) and can be configured in numerous ways:

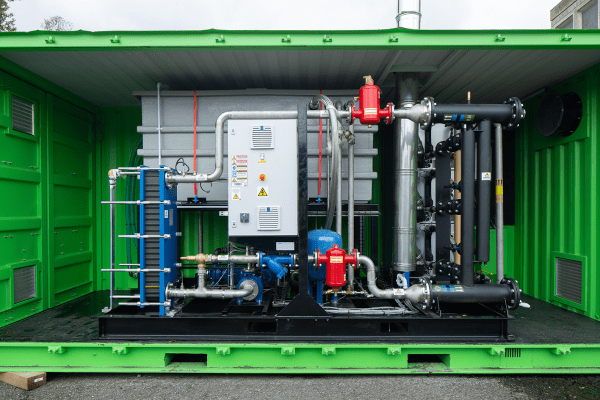

Mounting Options – Directly coupled and flange mounted, these pumps can be supplied as bare-shaft, skid-mounted, trolley-mounted, trailer-mounted, or truck-mounted. They can even be mounted on underwater ROVs.

Drive Options – Harben Pumps are available with diesel, electrical, or hydraulic drive options, providing flexibility to suit any operational requirement.

Conclusion: The Ultimate Pump for Professionals

For anyone working in the drain and sewer industry, the Harben Pump is more than just a tool – it’s a partner in efficiency, reliability, and innovation. From its groundbreaking history to its cutting-edge design, the Harben Pump stands as a testament to Flowplant Group Ltd’s commitment to excellence. Whether you’re tackling tough clogs or maintaining extensive sewer systems, trust the Harben Pump to deliver unmatched performance every time.

Resources:

https://www.youtube.com/watch?v=0MPMXYybGD8&t=2s

https://www.flowplant.com/product-category/jetters-pumps/high-pressure-pumps/harben-pumps/