News

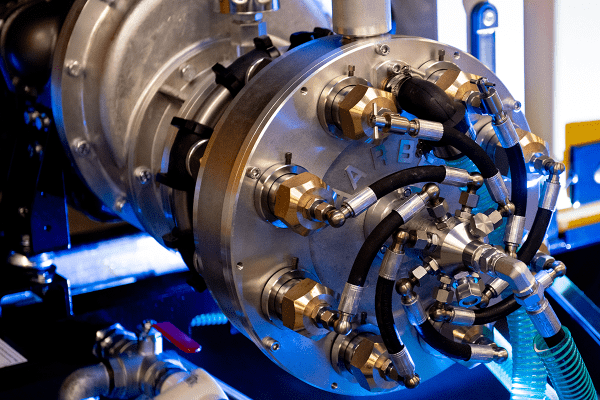

The Importance of Regularly Inspecting Pump Seals and Hoses

When it comes to maintaining the efficiency, reliability, and safety of high-pressure pumps, inspecting seals and hoses regularly is paramount. Here’s why these inspections are crucial and how they benefit your operations.

Regular Seal Inspections: Key Benefits

- Prevent Leakage:

Seals are critical in containing the fluid within the pump system. Regular inspections help identify any wear or damage early, preventing leaks that can lead to fluid loss and reduced operational efficiency.

- Maintain Efficiency:

Worn or damaged seals can cause the pump to operate less efficiently, resulting in higher energy consumption and decreased performance. Regular inspections ensure that seals are in good condition, maintaining optimal pump efficiency.

- Avoid Contamination:

In applications involving sensitive or hazardous fluids, seals prevent contaminants from entering the pump system. Regular checks ensure seal integrity, thus avoiding contamination that could affect product quality and safety.

- Extend Pump Lifespan:

Identifying and addressing seal issues early can prevent further damage to other pump components, effectively extending the overall lifespan of the pump.

- Ensure Safety:

Leaking seals can pose significant safety hazards, especially when dealing with hazardous or flammable fluids. Regular inspections help mitigate these risks, ensuring a safer working environment.

- Cost Savings:

Preventative maintenance, including regular seal inspections, can save significant costs associated with emergency repairs, downtime, and lost production due to pump failures.

- Compliance:

Many industries have regulatory standards that require regular maintenance and inspection of equipment, including pumps. Ensuring seals are in good condition helps comply with these regulations, avoiding potential legal and regulatory penalties.

Daily High-Pressure Hose Inspections: Essential Reasons

- Safety:

High-pressure hoses, if they fail, can cause serious injuries or fatalities. Daily inspections help identify wear, damage, or potential failures before they become hazardous, ensuring the safety of personnel.

- Prevent Leaks:

High-pressure hoses transport fluids under significant pressure. Daily inspections help detect leaks early, preventing environmental contamination and ensuring efficient operation.

- Maintain System Integrity:

The performance of high-pressure systems depends on the integrity of their hoses. Regular inspections help maintain consistent pressure and flow, ensuring the system operates as designed.

- Avoid Downtime:

Identifying potential issues before they cause a failure can prevent unexpected downtime. This proactive approach helps maintain productivity and reduces the risk of costly interruptions.

- Extend Hose Lifespan:

Regular inspections and maintenance can extend the lifespan of high-pressure hoses by ensuring they are in good condition and addressing minor issues before they escalate.

- Cost Savings:

By preventing hose failures and the associated damage to equipment and lost productivity, regular inspections can save significant costs in repairs and downtime.

- Compliance:

Many industries have strict regulations regarding the maintenance and inspection of high-pressure equipment. Regular inspections help ensure compliance with these standards, avoiding legal and regulatory penalties.

Recommended Inspection Routine and Handy Checklist

To ensure the highest standards of operational safety and efficiency, we recommend that high-pressure hoses be checked on a daily basis, before issue, before test, and before use. To assist you with this, we’ve created a handy High-Pressure Hose Inspection Checklist, which you can download for further guidance, see below.

In conclusion, inspecting seals and hoses is a critical aspect of maintaining the reliability, efficiency, and safety of high-pressure systems. By integrating these inspections into your routine maintenance schedule, you can prevent leaks, ensure operational efficiency, avoid contamination, extend equipment lifespan, and comply with industry regulations. Regular inspections are an investment in the long-term health and productivity of your equipment and operations.