News

Preparing Your High-Pressure Pumps for Heavy-Duty Jobs: Best Practices

Preparing Your High-Pressure Pumps for Heavy-Duty Jobs: Best Practices

High-pressure pumps are the backbone of many heavy-duty jobs, from industrial cleaning to oil and gas operations. To ensure your pumps perform at their best, particularly when tackling tough tasks, a thorough preparation routine is essential. Follow our guide to preparing your high-pressure pumps for heavy duty jobs: best practices for maintaining and preparing your pumps and extending lifespan, alongside also boosting efficiency, safety, and overall performance.

Here are some key best practices for getting your pumps ready for heavy-duty jobs:

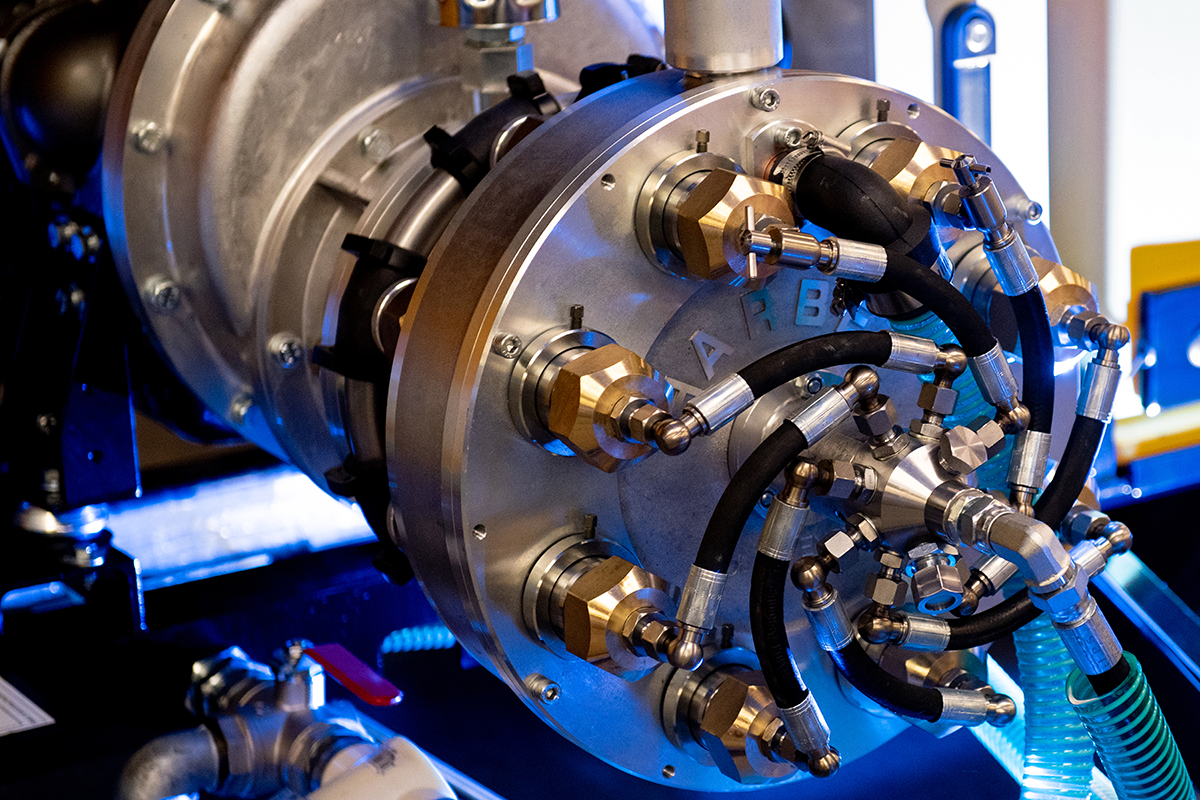

- Inspect Seals and Valves

Seals and valves are critical components that ensure your pump operates at optimal pressure and flow. It is crucial to regularly check or inspect these parts for wear and tear. Worn seals can lead to leaks, reducing the pump’s performance and leading to costly downtime. Small leaks on high pressure equipment can very quickly become much worse and create additional maintenance requirements. Replacing or repairing these components before they become a problem will keep your pump running efficiently.

- Check Fluid Levels

Proper lubrication is key to preventing overheating and reducing friction in your pump. Before beginning any heavy-duty task, make sure the oil and coolant levels are topped up. Regularly changing the hydraulic fluid, especially if you’re working in demanding conditions, can also help maintain smooth operation and extend the life of your pump.

- Evaluate the Hose Condition

The integrity of high-pressure hoses plays a huge role in overall system performance. As we’ve previously discussed [link to 6 – BLOG – Pressure losses in hoses and how this effects jetting performance], pressure loss in hoses can impact jetting efficiency. Before engaging in a heavy-duty task, inspect hoses for cracks, leaks, or weak points. Replace any damaged hoses and ensure fittings are properly secured to avoid pressure drops and ensure full power output.

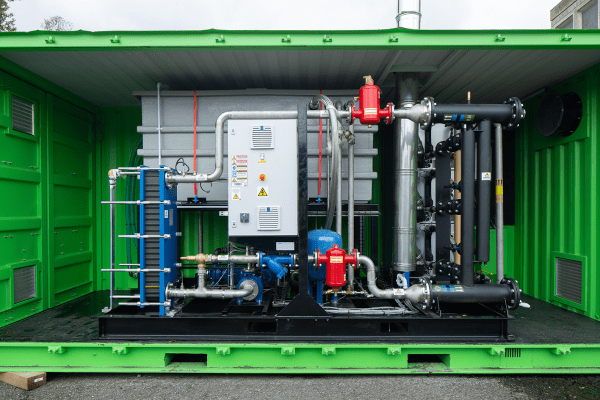

- Examine the Pumping Environment

Heavy-duty jobs often involve harsh environments that can challenge your equipment. Whether you’re dealing with abrasive materials or extreme temperatures, it’s important to assess how environmental factors might affect your pump. Install protective gear or make necessary adjustments to reduce the risk of damage, overheating, or clogging.

- Test the Pump’s Pressure Levels

Before diving into a heavy-duty job, always test the pump’s pressure levels. This ensures that the pump is performing as expected and that there are no unseen issues that could hinder performance. Use a pressure gauge to check that the system is maintaining the required pressure for the task at hand.

- Ensure Nozzle Compatibility

Using the wrong nozzle can undermine your pump’s efficiency and effectiveness, especially when handling a high-pressure system. Choose the right nozzle for the job to ensure the pump operates at the correct pressure and flow rate. Nozzle wear should also be checked, as damaged or worn nozzles can alter the system’s performance.

- Conduct a General System Check

Before any heavy-duty operation, perform a complete system check to make sure everything is functioning correctly. This includes verifying electrical connections, checking for unusual sounds or vibrations, and ensuring that all safety mechanisms are operational. A final walkthrough of the system will help catch potential issues before they become costly problems during the job.

- Monitor Performance During Use

Once the heavy-duty job is underway, continuously monitor the pump’s performance. Check for pressure fluctuations, strange noises, or other signs that something may be off. Prompt action can help prevent equipment damage and extend the lifespan of your pump.

Conclusion

Proper preparation is the key to maintaining the reliability and efficiency of your high-pressure pump in heavy-duty jobs. A proactive approach—regularly inspecting seals, checking hoses, and monitoring pressure levels—will not only prevent unnecessary breakdowns but also maximise productivity and ensure smooth operation. By incorporating these best practices into your pump maintenance routine, you’re safeguarding your equipment and ensuring that it’s ready to tackle even the toughest tasks.

For further guidance on preparing and maintaining your high-pressure equipment, Flowplant Group Ltd offers a range of services and expert advice. Contact us today to learn more about how we can support your operations.