Custom Build High Pressure Systems

Custom Build High Pressure Systems

Flowplant can offer consultancy and technical assistance on a wide range of custom build high pressure systems for fluid pumping applications. We are able to provide custom design solutions across all applications. Some of our recent projects include:

Flowplant can offer consultancy and technical assistance on a wide range of custom build high pressure systems for fluid pumping applications. We are able to provide custom design solutions across all applications. Some of our recent projects include:

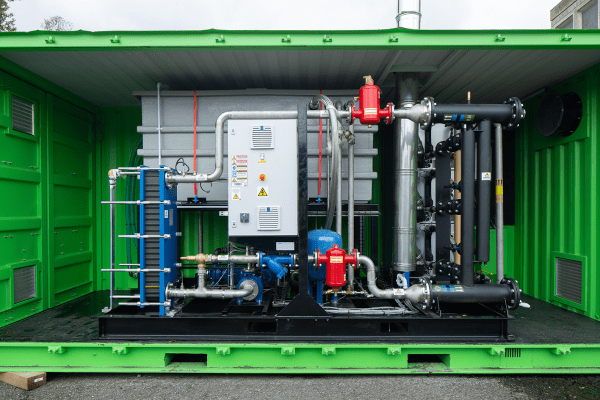

Multi skid water jetter for local installation

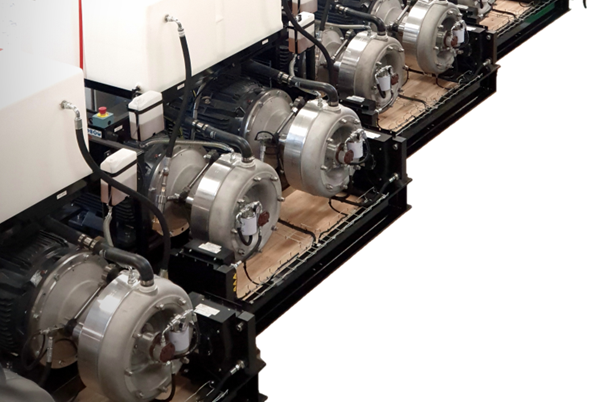

High pressure pump skid for use in a nuclear reactor

Recycling system for waste material

High pressure test rig with fast fill and chemical injection

Umbilical flushing unit with severe space limitations

Drain jetters for Zone 2 hazardous area

High pressure filter test rig

Broad Experience

Our experience of custom build high pressure systems and low viscosity water based hydraulic fluids has proved invaluable to many of our clients, saving them money and reducing downtime. Flowplant’s engineering knowledge extends beyond that generally found in the oil hydraulics industry and our experience with high pressure control valves up to 1000 bar is often of particular value. Our sales engineers are happy to visit client sites, see the issues first hand and call on 50 years of application experience to provide compliant custom designed and cost-effective solutions.

Life Long Service

Our custom build high pressure systems are constructed to exacting standards. To remain compliant and operating at optimum efficiency equipment must be serviced and maintained by trained and competent engineers. We provide full after sales service packages from our UK factory or any of our UK based ISO 9001:2015 quality assured service centres. Factory based service training schools, designed to meet customer’s needs, can be arranged for those companies wishing to maintain their own machinery. Alternatively, our overseas clients have the option of using one of the ever growing group of Flowplant distributors; many have been supplying local back up for our pumps and systems for decades.

Project Managing Custom Build High Pressure Systems

Many of our supply contracts involve Flowplant building equipment that is on the critical path of much larger projects – construction of PLSV’s and FPSO’s being such examples. At Flowplant, our engineers and project managers understand the importance of on time deliveries and they provide timely and accurate project updates allowing our clients to plan and schedule their overall project. They know that supplier document requirement lists (SDRL’s) are a vital part of the build process and they encourage full client participation during the construction process and FAT procedure. We welcome feedback on all our projects, believing that this is the way to improve on every machine we deliver, turn our customers into partners and keep them coming back.

Showing the single result