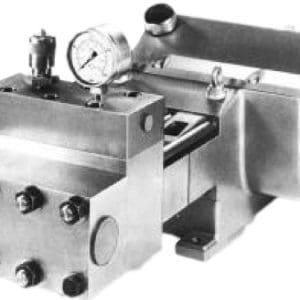

H-200 SAP

- Pressure to 1500 bar and flows up to 180 l/min

- Choice of 8 different plunger sizes to achieve a range of pressures and flow rates

- Horizontal or vertical mounting options

- Tungsten carbide plungers

- Crankcase with forced lubrication, filtration and oil cooling

- Simple design with easy maintenance

- Integral reduction gearbox

- Fitted with INTELLIVALVE TECHNOLOGY to reduce number of components, reduce maintenance time and increased component lifetime

Description

The HPP is a European brand, specialised in the design and construction of high pressure plunger pumps. They offer a wide range of products to meet requirements that go from 50 to 400kW, with pressures up to 2800 bar.

The pumps are manufactured using the latest modern technologies with regards to both materials used, machining and mechanical operations, and heat treatments.

Model H-200 SAP is a triplex plunger pump, capable of pressures up to 1500 bar (21,755 psi) and flows to 180 l/min (39.6 UKgpm / 47.6 USgpm). It is available with 8 plunger sizes and 2 gearbox ratios providing numerous pressure and flow combinations to suit many applications.

Drive power can be diesel or electric and the gearbox is integral to the crankcase making the design extremely compact. The crankcase features forced lubrication with oil filtration and cooling, which ensures reliability and long service life.

The pump has been designed to allow for vertical or horizontal installation – the different configurations mean the units can be designed to take best advantage of the site conditions and space that may be available.

The H-200 SAP triplex plunger pump can be used in numerous pumping applications because it is efficient, reliable and easy to maintain.

- Water jetting / surface preparation

- Hydrostatic testing

- High pressure coolant pumping

- Hot steel descaling

- Water hydraulic systems

- Surface preparation

- Tube/pipe cleaning

| Ø plunger | rpm | gear ratio | pump rpm | lpm | UK gpm | US gpm | bar | psi | HP | kW | kg |

| 22 | 1500 | 3.1 | 478 | 55 | 12.1 | 14.5 | 1500 | 21,755 | 204 | 152 | 500 |

| 1800 | 3.8 | 475 | 54 | 11.9 | 14.3 | 1500 | 21,755 | 201 | 150 | 500 | |

| 24 | 1500 | 3.1 | 478 | 65 | 14.3 | 17.2 | 1300 | 18,855 | 209 | 156 | 500 |

| 1800 | 3.8 | 475 | 64 | 14.1 | 16.9 | 1300 | 18,855 | 208 | 155 | 500 | |

| 26 | 1500 | 3.1 | 478 | 76 | 16.7 | 20.1 | 1200 | 17,405 | 227 | 169 | 500 |

| 1800 | 3.8 | 475 | 76 | 16.7 | 20.1 | 1200 | 17,405 | 225 | 168 | 500 | |

| 28 | 1500 | 3.1 | 478 | 88 | 19.4 | 23.2 | 1000 | 14,505 | 220 | 164 | 500 |

| 1800 | 3.8 | 475 | 88 | 19.4 | 23.2 | 1000 | 14,505 | 217 | 162 | 500 | |

| 30 | 1500 | 3.1 | 478 | 101 | 22.2 | 26.7 | 800 | 11,605 | 201 | 150 | 500 |

| 1800 | 3.8 | 475 | 101 | 22.2 | 26.7 | 800 | 11,605 | 200 | 149 | 500 | |

| 32 | 1500 | 3.1 | 478 | 115 | 25.3 | 30.4 | 700 | 10,155 | 201 | 150 | 500 |

| 1800 | 3.8 | 475 | 115 | 25.3 | 30.4 | 700 | 10,155 | 200 | 149 | 500 | |

| 35 | 1500 | 3.1 | 478 | 138 | 30.4 | 36.5 | 600 | 8,705 | 205 | 153 | 500 |

| 1800 | 3.8 | 475 | 137 | 30.1 | 36.2 | 600 | 8,705 | 204 | 152 | 500 | |

| 40 | 1500 | 3.1 | 478 | 180 | 39.6 | 47.6 | 450 | 6,525 | 201 | 150 | 500 |

| 1800 | 3.8 | 475 | 179 | 39.4 | 47.3 | 450 | 6,525 | 200 | 149 | 500 |

- Pressure to 1500 bar and flows up to 180 l/min

- Choice of 8 different plunger sizes to achieve a range of pressures and flow rates

- Horizontal or vertical mounting options

- Tungsten carbide plungers

- Crankcase with forced lubrication, filtration and oil cooling

- Simple design with easy maintenance

- Integral reduction gearbox

- Fitted with INTELLIVALVE TECHNOLOGY to reduce number of components, reduce maintenance time and increased component lifetime